Making Controlled Drugs Cabinets

We manufacture all our own controlled drugs cabinets here at Pharmacy Medical HQ in Nottinghamshire. As a result we are able to offer you market leading quality, price and service. But how do we do it? We explain the process of making controlled drugs cabinets below…

The Process Behind Making Controlled Drugs Cabinets

Blank sheets of steel.

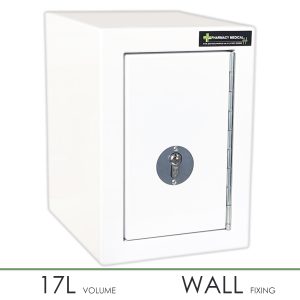

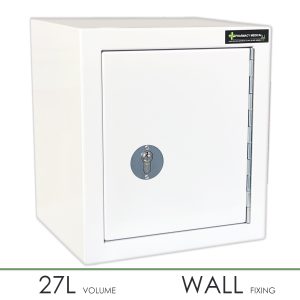

Our controlled drugs cabinets start out their life as flat sheets of cold reduced mild steel 2mm thick. BS2881:1989 level one (the requirement for controlled drug cabinets) requires a minimum of 1.5mm thick steel, we prefer to manufacture our drugs cabinets from thicker 2mm making them much stronger than most of our competitors.

The steel sheet blanks are guillotined to size, and any material notched to accommodate corresponding parts when the cabinet bodies are assembled.

Laser cut door blanks.

We use a Laser cutter to shape the steel blanks to form the door profiles which also incorporate the key hole and removes any necessary corners for clearance when bending.

Making Controlled Drugs Cabinets, Forming the drugs cabinet shape.

The blanks are then bent to the required shape using a machine called a “Press brake”. This machine exerts 60 tonnes of pressure on the steel through a top and bottom “V” shaped tool. This forms a tight bend in the steel to a predetermined angle. The bent cabinet bodies and doors are then passed on to other operators to be welded together.

Welding formed parts to make Controlled Drugs cabinet.

Operators assemble the body and sides of the cabinet then put small tack welds at various intervals along the joints to position the component parts prior to welding.

The Drugs cabinet doors are then offered to the cabinet to ensure the correct gap between the door and the cabinet. The Misuse of Drugs (Safe Custody) Regulations 1975 requires a maximum gap of 3mm between the door and the jam.

Another requirement of the Misuse of Drugs act is that anchor plates are placed over the holes through which the cabinet is fixed to the wall or floor. The anchor plates have to be a minimum size and thickness in order to comply with the act. Their purpose is to reinforce the area around the fixing holes to help prevent forced removal.

When the operator is satisfied with the cabinet fit it is fully welded, another requirement of the Misuse of Drugs (Safe Custody) Regulations.

We use a method of welding called TIG (Tungsten inert gas) which gives a very precise and neat weld therefore reducing the need for excessive dressing of the weld.

Powder coating the finished cabinet component parts.

The finished Controlled drugs cabinet assemblies are taken over to our purpose-built powder coating plant adjacent to our fabrication facility. Here they are degreased and thoroughly cleaned to remove all traces of grease and dirt.

The parts are then suspended from an overhead conveyor which will transport them around the whole powder coating process.

The paint process consists of a powder which is applied using an electrostatic gun. The gun applies up to 100,000 volts of positive static charge to the fine powder particles which is fired at and attracted to the negatively charged work pieces. These parts are electrically earthed so the charged particles will stick until melted and fused into a solid coat in the curing oven.

Our curing oven is a long tunnel through which the cabinet body assemblies are passed after the powder has been applied. This oven is at a constant 215 degrees centigrade and the cabinet parts need to be at that temperature for 12 – 15 minutes to allow the powder to form into a solid coating.

Upon exiting the oven on the conveyor the parts cool and are removed to be taken to the assembly bench.

Final assembly

Here the Controlled drugs cabinets are almost complete; the parts are checked and assembled to ensure they are compliant with both BS2881:1989 level one and Misuse of Drugs (Safe Custody) Regulations 1975.

Packaging and warehousing.

The finished Controlled drugs cabinets are then wrapped in protective foam and boxed for shipping.

We keep stocks of all our products so can usually despatch Drugs cabinets from our warehouse the next working day.